In this tutorial, we will learn about Position Sensors. Position Sensors play an important role in our daily lives as they are abundant in domestic products, automobiles, and in office or industry places, etc. Position Sensors, as the name indicates, provide feedback on the position of the measurand (quantity being measured).

Outline

Toggle- Introduction

- Types of Position Sensors

- Resistance Based or Potentiometric Position Sensor

- Capacitive Position Sensors

- Inductive Position Sensors

- Linear Variable Differential Transformer (LVDT)

- Inductive Proximity Sensors

- Hall Effect Based Magnetic Position Sensors

- Eddy Current Based Position Sensor

- Rotary Encoders

- Optical Position Sensors

- Fiber Optic Position Sensors

Introduction

Position sensors provide motion control, counting and encoding tasks by determining the presence or absence of a target or by detecting its direction, speed, motion or distance.

A position sensor can detect the position of an object or disturbance of electric or magnetic field and convert that physical parameter into an output electrical signal to indicate the position of the target.

As the technology improves, the sensing devices continue to get smaller, more inexpensive and better at performance, opening a gateway for more applications.

Also Check: Types of Biosensors

Types of Position Sensors

Position sensors are generally divided into two types based on the way of sensing.

They are

- Contact Devices

- Non-contact Devices

As the name indicates, the contact types of position sensors have the physical contact with the measurand. The contact based sensors are Limit Switches and Resistance based position sensors. Contact based sensors provide simple and low cost solutions in applications where physical contact with the object is acceptable.

Non-contact devices don’t involve in physical contact with the object. They are magnetic sensors, proximity sensors, Hall Effect based sensors and ultra-sonic sensors.

Every position sensor has its benefits and limitations. The goal is to select a sensor that is a cost effective solution for parameters of a specific application.

Resistance Based or Potentiometric Position Sensor

Resistive position sensors are also called as Potentiometers or Position Transducers. They are originally developed for applications in military use. They were used in radios and televisions as panel mounted adjustment knobs. Potentiometers can work as linear or rotary position sensors.

Potentiometer doesn’t require a power supply or extra circuitry to perform their basic position sensing function. Hence, they are passive devices. They are operated in two modes: voltage divider and rheostat. In rheostat, the resistance varies with motion. Hence the applications make use of this varying resistance between fixed terminal and a sliding contact. Voltage divider has the true potentiometric operation. In this, a reference voltage is applied across a resistive element. The position of the movable wiper is determined by calculating the voltage picked up by the wiper.

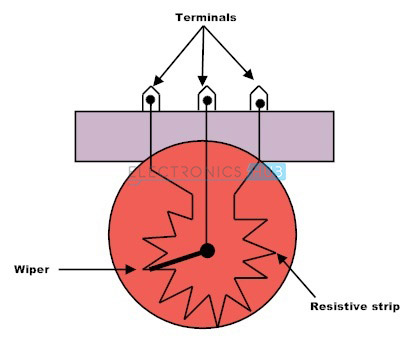

Potentiometers are the most commonly used position sensors. It has a fixed terminal and a wiper terminal connected to a mechanical shaft. The movement can be either linear (slide) or angular (rotational). This movement causes the resistance between fixed and wiper terminals to change. The output electrical signal which is generally voltage varies in proportion to the position of the wiper resistive track and hence the value of the resistance.

Potentiometers are available in different sizes and designs. The commonly available types are linear slider and rotational type. When it is used as position sensor, the object is connected to its slider.

A reference voltage is applied between the fixed terminals which are on the either side of the wiper and the output voltage is taken from this wiper. This configuration forms a voltage divider network and the output voltage is dependent on the position of the slider.

If a potential of 12 V is applied to the potentiometer, a maximum of 12 V and a minimum of 0 V is available as the output voltage. Depending on the position of the wiper, the output voltage can be any value between 0 V to 12 V. If the wiper is at the center of the resistive track, the output voltage is 6 V.

The construction of a potentiometer is shown in the below figure.

For general purpose position sensing, a low cost potentiometer is sufficient. The advantages of the potentiometers are low cost, simple operation, simple application theory, easy to use and robust EMI susceptibility. The disadvantages are eventual wear-out due to sliding wiper, lesser sensing angle and low accuracy. The main disadvantage of potentiometer based position sensor is its physical size as it limits the movement of the slide and hence the output signal. The sensing angle of a typical potentiometer is in the range of 00 to a maximum between 2400 and 3300. Vernier turns can be applied to achieve multi-turn capability.

A simple position sensing circuit is shown below.

It consists of an OP amp and a potentiometer based position sensor. The output voltage depends on the position of the wiper.

Carbon film is the most common type of resistive track used in potentiometers. But there is a contact noise that is superimposed in the expected resistance. Contact noise is the result of mechanical contact between wiper and resistive surface. This can cause up to 5 % of the total resistance.

Wire wound type potentiometers use a straight wire resistive element or coil wound resistive wire. The problem with wire wound potentiometers is the jumping of wiper between positions producing a logarithmic output signal.

Polymer film or cermet type potentiometers are available for high precision and low noise applications. These are made up of conductive plastic resistive material. They have very less friction between the wiper and the surface and therefore less electrical noise, good resolution and longer life. These are available as both single turn and multi turn devices. These devices are used in high accuracy applications like joysticks, industrial robots etc.

Capacitive Position Sensors

Capacitive Sensors are non-contact type of devices used for precision measurement of a target position if the target is conductive in nature, or used for measurement of thickness and density of a material if the target is non-conductive in nature. When used with conductive targets, they work irrespective of the material of the target as all conductors look same to a capacitive sensor. The thickness of the target is also not important as the sensors sense the surface of the target.

They are mainly used in disk drives, semiconductor technology and high precision manufacturing industries where high accuracy and frequency response are important. When used with non-conductive targets, they are generally used in label detectors, coating thickness monitors, and paper and film thickness measuring units.

They are primarily used in measurement of linear displacement from a few millimeters to nanometers. Capacitive sensors make use of the electrical property conductance for measuring position. The ability to store electric charge by a body is capacitance. The most common device used to store charge is a parallel plate capacitor. The capacitance of a parallel plate capacitor is directly proportional to the surface area of the plates and dielectric constant, and inversely proportional to the distance between the plates. Hence, when the spacing between the plates is changed, there is a change in its capacitance and capacitive sensors make use of this property.

The capacitance,

C = (εr εo A) / d

Where

εr is relative permittivity of dielectric

εo is permittivity of free space

A is the overlap area of plates

And d is distance between the plates

A typical capacitive sensing model consists of two metal plates with air in between them acting as dielectric. The sensor or probe is one of the metal plates and the target object which is conductive, is the other plate.

When a potential is applied to the plates of the conductor, an electric field is created between them by causing positive charges to collect on one plate and negative charges on other.

Capacitive sensors use alternating voltage. Alternating voltage causes the charges to continually reverse their positions. The alternating electric field between the capacitive probe and the target is monitored for changes and is used in measuring the capacitance between the probe and target. Capacitance is determined by the area of the surfaces, dielectric constant and spacing of the surfaces. In the majority of capacitive sensing applications, the size and area of the capacitive sensor and the target do not change. The dielectric material between the conductive surfaces doesn’t change. The only factor responsible for any changes in the capacitance is the distance or spacing between the capacitive sensor and the target.

Hence the capacitance is an indicator of the target’s position. Capacitive sensors are calibrated to produce an output voltage corresponding to the change in distance between the probe and target which causes the capacitance to change. This is called the sensitivity of the capacitive sensor. Sensitivity of a capacitive sensor is the amount of voltage change to a defined amount of distance change. Generally used sensitivity setting is 1 V / 100 µ m i.e. the output voltage changes 1 V for every 100 µ m change in distance.

A capacitive sensor probe consists of three components: sensing area, guard and body.

The potential is applied to the sensing area. There is a problem of spreading of an electric field to areas on the target other than the defined sensing area and the target. To prevent this from happening, a technique called guarding is used. In this technique, a guard area is created by surrounding the sides and back of the sensing area and is maintained at a potential same as the sensing area. As the guard and the sensing area are at the same potential, there will be no electric field between them. Any other conductors in the proximity other than the sensing area will form an electric field with the guard. The sensing area and the corresponding target are undisturbed.

Because of this guard, the electric field projection of the sensing area will be conical in nature. The electric field from the probe covers an area on the target of approximately 30 % larger that the sensor area. Therefore, it is essential to have a minimum target diameter as 30 % of the sensing areas’ diameter for standard calibration.

The range of a sensing probe is directly proportional to the size of the sensing area. Smaller probes must be placed closer to the target in order to achieve the desired amount of capacitance. The maximum allowable gap between the probe and the target is approximately 40% of the diameter of the sensing area. Beyond this, the probe becomes useless. There are applications where multiple probes are simultaneously used. In these applications, it is essential to synchronize the excitation voltage of all the probes. If the voltages are not synchronized, the probes interfere with each other as one probe may try to increase the electric field while the other decreases it. This gives a false reading.

The range of a sensing probe is directly proportional to the size of the sensing area. Smaller probes must be placed closer to the target in order to achieve the desired amount of capacitance. The maximum allowable gap between the probe and the target is approximately 40% of the diameter of the sensing area. Beyond this, the probe becomes useless. There are applications where multiple probes are simultaneously used. In these applications, it is essential to synchronize the excitation voltage of all the probes. If the voltages are not synchronized, the probes interfere with each other as one probe may try to increase the electric field while the other decreases it. This gives a false reading.

Capacitive Sensors can also be used with non-conducting targets. The dielectric constant of the non-conductive target is the basis for the operation. The dielectric constant of the non-conductive materials like plastic is different than air. When the non-conducting material is used as a dielectric medium between two conducting plates, its dielectric constant will determine the capacitance between the conductors.

The two conducting plates are sensor probe and a grounded conductive reference. The changes in capacitance and hence the output of the sensor will be corresponding to the changes in material thickness, density or composition.

The two conducting plates are sensor probe and a grounded conductive reference. The changes in capacitance and hence the output of the sensor will be corresponding to the changes in material thickness, density or composition.

There are high precision and high performance capacitive sensors that can measure a displacement of the order of nanometers. These high performance sensors are stable to changes in temperature, produce a linear output and have high resolution.

The advantages of capacitive sensors over other non-contact devices are high resolution, inexpensive and not sensitive to the material of the target. The capacitive sensors are not suitable in conditions where the environment is dry or wet and the distance between the probe and the target is large.

Inductive Position Sensors

Inductive Sensors are non-contact type of devices used for precision measurement of a target position if the target is conductive in nature. Inductive sensors are used to recognize any conducting metal target.

Capacitive sensors make use of electric field for sensing the surface of a conducting target. Inductive sensors make use of electromagnetic field that penetrates through the target. An inductive sensor probe consists of an oscillator that generates a high frequency electromagnetic field. This field is radiates from the sensing face of the probe.

When this field contacts a conducting metal target, a small current is induced within the metal target. These currents will generate their own electromagnetic field that interferes with the field originating from the probe. This causes a change in the amplitude of the oscillations of the signals from the probe. The output voltage can be calibrated to this change. When the probe is closer to the target, the more current reacts with the field originating from the probe and the output is greater.

Unlike capacitive sensors, inductive sensors are independent of the material in the gap between the probe and the target. Hence, they can be used in hostile environment where oil or other liquids may appear in the gap.

The material of the target is an important factor in inductive sensors. Materials like aluminum, steel and copper, each react differently to the sensor. Hence the sensor must be calibrated for each target to achieve optimum to highest possible performance.

Generally there are two types of target materials for inductive sensors. They are ferrous and nonferrous. Ferrous materials are magnetic in nature while nonferrous materials are nonmagnetic. Ferrous materials include iron and most steel materials while nonferrous materials include zinc, aluminum, copper and brass. Some inductive sensors will work with both ferrous and nonferrous target materials while others will work only with one type of material.

The size of the target is also important as the effective area of electromagnetic field of the probe will vary from sensor to sensor. It is a minimum requirement to have the cross sectional area of the target of at least 300 % of the probe’s coil diameter, i.e. ideally the surface area of the target must be at least three times the diameter of the probe.

The thickness of the target is also an important factor as the electromagnetic field will penetrate the target and creates electrical currents. The thickness of the target depends on the frequency of the signal which drives the probe and is inversely proportional to the frequency, i.e. when the drive frequency increases, the minimum thickness of the target decreases.

For a drive frequency of 1 MHz, the minimum thickness of some commonly used target materials is as follows:

- Iron—0.6 mm

- Stainless Steel—0.4 mm

- Copper—0.2 mm

- Aluminum—0.25 mm

- Brass—1.6 mm

Inductive sensors with analog output signals are known for their nanometer resolution, short response time, frequency responses of 80 KHz or more, repeat accuracy and immunity to environmental contaminants.

The output voltage and current of an inductive sensor is directly proportional to the distance between the surfaces of the sensor and the target, i.e. the voltage and current represent the absolute measured values corresponding to the distance. This property is used in numerous applications.

Linear Variable Differential Transformer (LVDT)

The Linear Variable Differential Transformer (LVDT) is a common type of electromechanical, high resolution, contact based linear position transducer. LVDT is one of the best available, reliable and accurate methods for measuring linear distance. LVDTs are used in computerized manufacturing, machine tools, avionics and robotics.

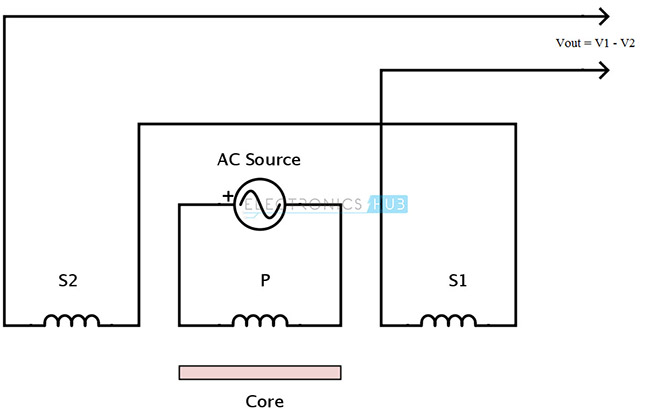

Linear Variable Differential Transformer is a position to electrical sensor. An LVDT consists of three coils, one primary and two secondary. A movable magnetic core is placed as shown in the figure. This magnetic core which is also called an armature controls the transfer of current between primary and secondary coils in the LVDT. The output of the LVDT is proportional to the position of the core.

A cross sectional view of the LVDT is shown below.

The magnetic core moves linearly inside the transformer consisting of a primary coil and the two identical outer secondary coils that are wound in a cylindrical manner.

When the primary coil is excited with an alternating current, a voltage is induced across secondary coils. The secondary coil voltage varies according to the position of the magnetic core between the coils which moves axially. The output electrical signal is equal to the difference between the voltages across the secondary windings. Therefore the output voltage is proportional to the linear mechanical movement of the magnetic core.

A normal transformer style representation of the LVDT is shown below.

The schematic representation of an LVDT is as shown below.

Working of LVDT:

The primary coil of the transformer is energized by applying an alternating source of constant amplitude. This generates a magnetic field and the developed magnetic flux is coupled to the secondary coils S1 and S2 by the magnetic core in the center. The secondary coils are wound out of phase with each other. Therefore, when the position of the core is exactly midway between the two secondary coils, equal amount of magnetic flux is coupled to S1 and S2. The voltages induced in each of the secondary coils V1 and V2 are equal. Hence the output differential voltage Vout is equal to zero.

V1 = V2

And

Vout = V1 – V2 = 0

When the coil moves away from the center, the voltage induced in each secondary coil is different. When the core is moved towards S1, the magnetic flux coupled with S1 is greater than that is coupled with S2. Therefore the induced voltage V1 increases and V2 decrease.

The differential output voltage is Vout = V1 – V2.

If the magnetic core or armature moves towards the secondary coil S2, the magnetic flux coupled with S2 is greater than S1. And the induced voltage V2 increases while V1 decreases.

Therefore,

the output voltage is Vout = V2 – V1.

The phase of the output signal can determine the position of the core.

Simply the output voltage of LVDT will not determine the position of the core if there are any mismatches between the secondary coils or any leakage inductances. A signal conditioning circuit is useful in removing these difficulties.

A normal LVDT is shown below.

LVDT with the signal conditioning circuit is shown below.

It consists of additional filtering and amplification circuit where the absolute values of the two output signals are subtracted. The absolute value circuit can be formed from a diode capacitor rectifier. Filters are used to detect the amplitude of both the secondary voltages. This technique is useful in measuring both the positive and negative variations about the center position.

LVDT has a huge advantage over the potentiometer as a position sensor in many ways. Since the magnetic core doesn’t touch the coils, there is no mechanical contact between the coils and the core. Hence a frictionless operation is achieved and is useful in testing and high resolution devices. This is also an important factor in their longer operation life.

Because of its electromagnetic coupling principles and frictionless operation, LVDT can measure infinitesimally small changes.

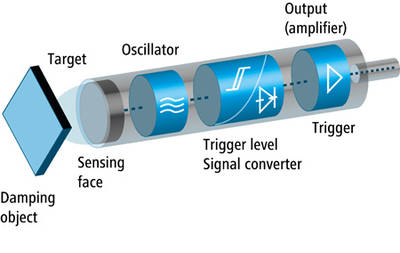

Inductive Proximity Sensors

Inductive Proximity Sensors are low cost, solid state and non-contact based devices. They are basically used to detect metal objects which are both ferrous and non-ferrous in nature. The basic components of an inductive proximity sensor are a coil, an oscillator, a detection circuit and an output circuit.

When an alternating current is passed through the coil, it generates a high frequency magnetic field. If a metallic object comes near to this field, the inductance of the coil changes. Eddy currents induced in the object by the field will change the amplitude of the oscillations. The demodulator will detect the changes in amplitude and converts them into a DC signal. This DC signal trips the trigger and the output stage switches.

Without any additional equipment, the inductive proximity sensor can operate electromagnetic clutches, brakes and valves. To actuate the sensor, a metal of any shape and size or a pneumatic cylinder or a machine tool carriage or a drill bit can be used.

The inductive proximity sensor ignores non-metallic objects like oil, water, dirt, etc. It withstands in shock environments and is short circuit resistant.

They are used in industry automation for counting the products, in security systems as metal detectors and in military applications in detecting landmines and other arms.

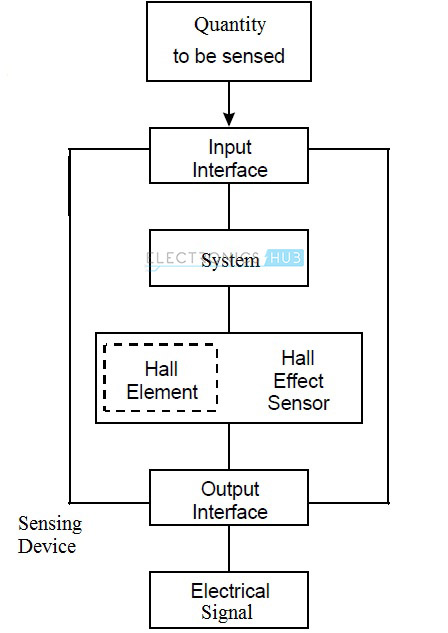

Hall Effect Based Magnetic Position Sensors

Magnetic Position Sensors are used to determine the position of objects by detecting the strength or direction or presence of magnetic fields generated from the Earth, electric currents, magnets and even brain wave activity. Magnetic position sensors are non-contact devices and are very important in many industries and navigation systems.

The magnetic field is a vector quantity that has both magnitude as well as direction. Some sensors measure magnitude, but not direction of the magnetic field. These are scalar sensors. Other sensors measure the magnitude of the component of magnetization along their main sensitive axis. These are uni-directional sensors. Some sensors include direction of the field along with its magnitude. These are bi-directional sensors.

Hall Effect sensor is a magnetic field sensor and can be used in sensing position, pressure, current, temperature and many more.

A general Hall Effect sensor is shown below.

Hall Effect devices when used as position sensors can be very accurate and affordable. Hall Effect sensor consists of a Hall element which is constructed from a thin sheet of conductive material. The output connections of the hall element are perpendicular to the direction of current flow. When a Hall Effect sensor is subjected to a magnetic field, it reacts with an output voltage that is proportional to the strength of the magnetic field. Additional electronic circuits like signal conditioning circuits are required to achieve useful voltage levels as the original output voltage is very small. Hence, a basic Hall Effect Sensor consists of a Hall element combined with a signal conditioning circuit on an integrated circuit.

The principle of Hall Effect states that, “when a current carrying conductor is placed in a magnetic field, a voltage is generated which is perpendicular to both current and magnetic field.”

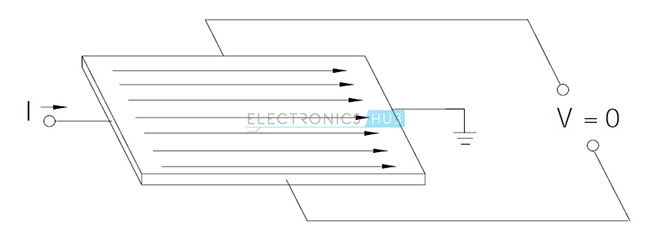

Consider a thin sheet of conductive material. Current is passed through this and the output connection is perpendicular to the direction of the flow of current.

In the absence of a magnetic field, the current distribution is uniform and there is no potential difference in the output.

In the presence of a magnetic field perpendicular to the direction of the current, a Lorentz force is exerted on the current. This force disturbs the current distribution and results in a potential difference at the output.

Hall Effect based position sensors are available with digital and analog output. In digital output sensors, the output is in either ON state or OFF state. Digital Hall Effect sensors are of two types: Bipolar and uni-polar. Bipolar sensors require positive gauss which is the South Pole to operate and negative gauss which is the North Pole to release. Release is obtained by moving the positive gauss or South Pole away from the sensor. Uni-polar sensors require a single magnetic pole to operate.

In analog output sensors, the output voltage is continuous and is dependent on the strength of the magnetic field. The output voltage increases or decreases with a strong or a weak magnetic field respectively. They operate by proximity to either of the magnetic poles.

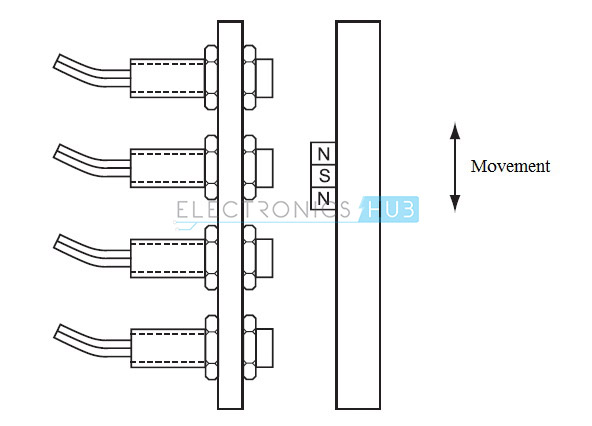

Consider the following arrangement of a Hall Effect based position sensor.

It consists of four uni-polar sensors with digital outputs and these four sensors are connected together and housed in an aluminum casing. These sensors are actuated by four individual magnetic actuators connected to a hydraulic system. The sensors generate event signals which represent the distance measured from a reference surface. These signals define the acceptable limits between which the object under test must generate electrical signals.

The following setup is used to achieve an accuracy of 0.002 inches of linear positioning. It consists of four bipolar sensors with digital outputs. They are actuated by a magnet mounted on a rod.

The advantages of Hall Effect sensors are long life, high speed and a temperature range of -40 0C to 150 0C.

Eddy Current Based Position Sensor

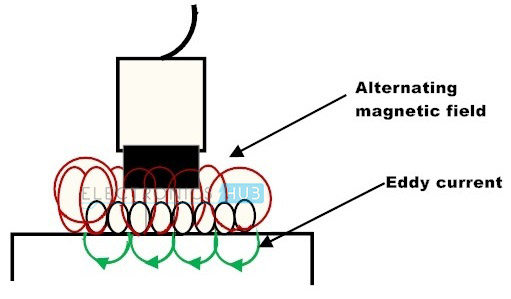

Eddy Current sensors are non-contact based devices used to measure the position, displacement, oscillation and vibration of a conductive target. Eddy current sensors are used in applications where high precision is required and the operating environment is harsh.

Eddy current sensors work on the principle of magnetic induction. A simple Eddy current sensor consists of a driver and a sensing coil. When an alternating current is passed through the coil, it generates an alternating magnetic field. When a target comes in contact with this field, a small current is induced in the target. These currents are called Eddy Currents. The Eddy current in the target will create a field which opposes the field of the sensor and resist the field. The distance between the sensor and the target is the factor in interaction of the two magnetic fields. Hence, the output voltage is calibrated to the change in field interactions, which is dependent on the distance. The surface area of the target must be at least three times the diameter of the probe.

The advantages of Eddy Current Sensors are less expensive, tolerance to harsh and dirty environment, smaller in size and not sensitive to the type of material used in the gap between the sensor and target.

Eddy current sensors are less useful in applications where high resolution is required and the gap between the sensor and target is large.

Rotary Encoders

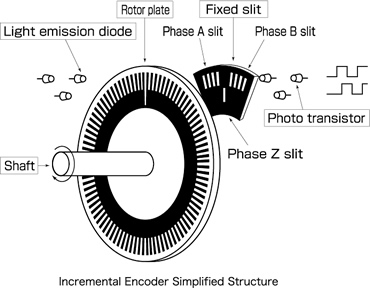

Rotary Encoder is an electromechanical device which converts angular motion to analog value or digital code. It is also called Shaft Encoder. Rotary encoders provide value as the shaft or axle of the encoder rotates. An output signal is produced that is proportional to the angle of the rotation. Based on the output signal, there are two types of encoders: incremental and absolute.

The output of an Incremental Encoder is in the form of a square wave and provides information about the motion of the shaft. This information is processed into speed, position, distance and RPM.

The output of absolute encoders is in the form of absolute measure of position, i.e. they indicate the current position of the shaft. This makes them Angle Transducers. Both incremental and absolute encoders are available in two construction designs: optical and mechanical.

In applications where mechanical motion must be processed into digital information, the most popular choice of sensors is incremental encoders.

The structure of an incremental encoder is shown below.

Incremental encoders provide output of pulse string that is proportional to the rotational displacement of the shaft i.e. it provides output only when the shaft of the encoder is rotated. To determine the amount of rotation, a counter is used that counts the number of output pulses. From a certain input shaft position, for the encoder to detect the amount of rotation, the count in the counter is reset at a reference position and from that position the number of pulses is added by the counter. The reference position can be anywhere and the count can be unlimited.

Incremental encoders are available in two channel types: single channel encoder and quadrature encoder. When the systems rotate in one direction, then single channel encoders are used. These are generally called Tachometers and provide only position and velocity information. Quadrature encoders have two output signals that are phased 900 apart. Hence quadrature encoders provide hi speed bi-directional information for complex motion applications.

Incremental optical encoders are used in applications where high RPM’s with high precision are calculated. Mechanical incremental encoders are generally used as digital potentiometers and require de-bouncing.

Absolute encoders produce a unique binary code output for each distinct angle of the shaft. The code can be gray code, excess gray code or natural binary code. The shaft position is always known in case of absolute encoders even after power failures.

The structure of an absolute encoder is shown below.

Optical absolute encoders consist of a glass or plastic disc with opaque and transparent areas. A light source like an LED and an array photo detectors are used to read the optical pattern resulting from the position of the disc at any time.

Optical Position Sensors

Optical sensors convert light signals into electric signals. They are non-contact based sensors. It is similar to a photo resistor and measures the physical quantity and translates into a form that is readable by any appropriate instrument. Optical sensors can measure the following physical measurands: temperature, pressure, flow, liquid level, displacement, position, rotation, vibration, acceleration, force, velocity, strain, radiation, pH, magnetic field, electric field, acoustic field.

Generally, the system employing optical sensor, includes three subsystems: a light source, a measuring device and an optical sensor. This is connected to an electrical trigger which reacts to changes in the signals in light sensor.

The example of an Optical Position Sensors is Position Sensitive Detector (PSD). Position sensitive detectors detect position data of incident light. Position sensitive detectors can track very small position changes. Position sensitive detectors can provide a high speed response, high reliability and high position resolution.

Fiber Optic Position Sensors

Fiber optic sensors use optical fibers as the sensing device. They can be used to sense temperature, strain, pressure, displacement, velocity and acceleration. The fiber optic position sensors make use of retro reflectance of light inside an optical fiber because of the movement of the proximal mirror surface. Fiber optic position sensors are immune to electromagnetic radiation, magnetic fields, lightning and many other harsh environmental conditions. They are generally used in long distance position sensing.

A fiber optic position sensor consists of two parts: an optical technique embedded in a passive sensor and an active controller. These two are connected by a full duplex fiber optic link. The controller is used to send the light signals. It transmits a burst of light in the form similar to bar code to a code disc. The disc rotates and the code incident on the disc will be unique at every position. Only at a specific wavelength, the bar reflects the light and specific colors of light are returned to the controller over a separate fiber optic cable. The light is analyzed in the controller for wavelengths and an appropriate binary output is produced.

Fiber optic sensors are of two types: intrinsic and extrinsic sensors.

In intrinsic sensors, the measurand modulates the transmission properties of sensing optical fiber. The properties are intensity, polarization, phase, etc.

In extrinsic sensors, the modulation takes place outside the fiber. Here the optical fiber just acts as a conduit to transport light from and to the sensor head.

The advantages of fiber optic position sensors are:

- Immune to electromagnetic radiation.

- Consists of electrically insulating material.

- Wide temperature range.

- Ability to multiplex signals.